Occasionally a customer will ask InterConnect how many breaches in a wire’s insulation is acceptable. The answer is an easy one; there should not be any breaches in the insulation of any wire inside an aircraft. So why is that? And, what is a breach?

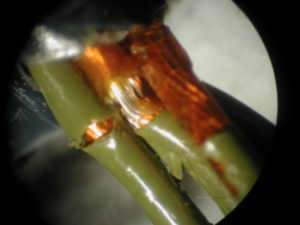

A breach in the insulation of a wire is when the insulation no longer covers the conductor. Figure 1 below shows a breach in F-16 Kapton wire. This breach was probably caused by chaffing of the wire against an object.

Figure 2 shows more F-16 wires that are breached. Older F-16s were made with Kapton insulation. These older F-16s were color-coded according to a wire’s gauge. The color code scheme as follows:

- Black: 26 gauge

- Green: 22 gauge

- Red: 20 gauge

- White: 18 gauge

- Yellow: 12 gauge

The green color shown in Figure 2 below represents 22 gauge wire. When you look at these wires you see: (a) green, which is the paint for the color code, (b) orange, which is the Kapton insulation, and (c) silver, which is the conductor of the wire. The wire on the far left has a small breach that you can see because the silver conductor is apparent. The middle wire has a large breach in it. The green paint is breached as well as the orange Kapton insulation leaving the silver conductor exposed. The wire on the far right is not breached to the conductor. The green paint is breached but the Kapton insulation is not.

The breaches observed in Figure 2 were probably caused by bending of the wires around some object. Because there are two wires adjacent to each other this breach is worse than others. When there are two or more breaches next to each other there is a chance of a short circuit which can lead to intermittent signals, arcing, and fires.

Aircraft wires are designed to be resistant to breaches. At the same time, they are designed to be lightweight and small in diameter. Thus, aircraft design engineers must make a decision as to how much protective insulation should cover wires, while at the same time try to reduce the size and weight of the wires on an aircraft.

When InterConnect makes wiring harnesses, none are shipped with breaches. If we accidentally nick or damage a wire during the manufacturing process, we replace the wire. It is unacceptable to have breaches in any wire. Breaches can lead to many problems in an aircraft and can even cause the loss of an aircraft, pilot and crew. InterConnect uses DITMCO wiring analyzers to test each wiring harness to make sure there are no breaches in any wire.

Bottom line is any breach in a wire’s insulation is bad. In our next blog, we will show how breaches in Kapton insulation wires can lead to arcing and fires. Stayed tuned!