Rewiring an aircraft is a very challenging task. Rewiring a fighter jet is even more challenging than other military aircraft because of the limited space and the fact that almost all of the equipment (i.e. Line Replaceable Units or LRUs) need to be removed to get to the wiring harness bundles.

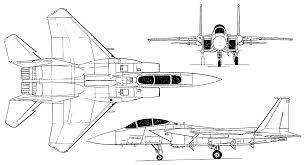

The purpose of this blog is not to provide the pros and cons about whether to rewire a military aircraft but to simply list what is needed to rewire a fighter aircraft (in this case an F-15 fighter aircraft). In order to rewire an F-15 the following 8 items are needed:

- Engineering Drawings to Assemble Replacement Wiring Harnesses

The first item needed to rewire an F-15 is the engineering drawing for the replacement wiring harnesses. These drawings include: 1) the Bill of Materials (BOM AKA parts list), 2) the from-to routing information for every wire in all of the wiring harnesses that make up an F-15, 3) the tooling to assemble each wiring harness; most commonly a full-scale drawing of the layout of the wire harness bundle that includes wire lengths and breakout locations (in many cases this tooling is called a Harness Assembly Drawing [HAD]), and 4) the manufacturing and assembly specifications for a given aircraft.

- Wiring Harness Installation Drawings

Similar to the wiring harness engineering drawings, a complete set of wiring harness installation drawings is required in order to successfully rewire an F-15 aircraft. Wiring harness installation drawings are some of the most complicated engineering drawings to read and interpret and in most cases are very difficult to obtain. Wiring harness installation drawing show: 1) how each wiring harness is routed throughout the aircraft, 2) installation material required, and 3) other important useful information needed during the installation process.

- Wire Insulation Decision

In most cases when an aircraft is rewired, a user will decide to change the primary type of insulation of the wiring. Many older aircraft used a type of insulation named Polyimide insulation (DuPont named this type of insulation Kapton™). Most military aircraft are rewired with another DuPont insulation named TKT™. TKT™ stands for Teflon/Kapton/Teflon. Other aircraft typically use an insulation named Crosslinked Tefzel™ or Spec 55™ wire. There are many benefits in changing the insulation type to these newer forms of insulation. They are almost the same size and weight while still offering many advantages.

- Installation Material

Companies who have little experience in rewiring military aircraft forget the program requires a substantial  amount of installation material. It is smart to replace the old installation material with new material. This material includes: clamps, brackets, washers, screws, nuts, nut clips, bolts, spacers, tapes, tubing, safety wire, teflon sheets, standoffs, posts, and adhesives. There are many different sizes for each of these items needed when rewiring a military aircraft.

amount of installation material. It is smart to replace the old installation material with new material. This material includes: clamps, brackets, washers, screws, nuts, nut clips, bolts, spacers, tapes, tubing, safety wire, teflon sheets, standoffs, posts, and adhesives. There are many different sizes for each of these items needed when rewiring a military aircraft.

- Special Wiring Harness Installation Tooling

The installation of many wiring harnesses requires special tooling. The special tooling includes teflon knives, flexible screwdrivers, and flexible mirrors. Additionally, many connectors must be terminated on-board the aircraft after a wire harness is installed. For this reason, wire harness termination tools such as wire strippers and crimpers must be available.

- Work Travelers for the Rewire

Rewiring an F-15 is a difficult task and it takes months to do. Without a very detailed plan where all steps are decided in advance, it should not be attempted. The work traveler should include which panels to open up, what equipment to remove, plus the order that wiring harnesses will be removed and then reinstalled. The traveler should also include which connectors will be terminated on-board the aircraft after the wiring harnesses are installed.

- Electrical Testing After Rewire

One of the items commonly debated after an aircraft is rewired is whether a “full blown” electrical test of an aircraft is needed or not. A full electrical test is expensive, takes weeks to write, and in most cases takes weeks to accomplish. The electrical test equipment can be made from a number of companies including DITMCO, Eclipse, or Cirris. For a full rewire it is highly recommended to do a full aircraft test. It is unwise to turn power on without electrically testing the aircraft first.

- Trained Workforce

The last item needed to rewire an F-15 fighter aircraft is a skilled workforce of aircraft maintenance technicians. This workforce does the removal and installation of wiring harnesses and other aircraft equipment. Most of this workforce should be licensed or trained Airframe and Power plant (A&P) technicians. Without skilled, experienced technicians no attempt should be made to rewire a military aircraft.

As you can see, rewiring a military aircraft is a complicated undertaking. There are many factors to consider. The end result, however, is that you have electrically a new aircraft. Having all new wiring harnesses will substantially reduce the number of intermittent problems an aircraft might experience. New wiring will also help safeguard the aircraft from electrical mishaps and increase the operational readiness rate. For laboratory test results of the condition of wiring harnesses removed from two 20+ year old F-16s, click below under Free White Paper!

Footnote: InterConnect Wiring has rewired or supplied the wiring harnesses to rewire many military aircraft over our 20+ year history. These aircraft include F-16s, F-15s, UH-60s, UH-1s, AH-1s, F-2s, and MH-60s. InterConnect’s largest contract to date was to supply 73 ship sets of wiring harnesses to rewire F-15s. Along with the F-15 wiring harnesses, this contract included rewiring all of the electrical power distribution panels (i.e. circuit breakers panels) and relay panels as well as supplying all of the miscellaneous installation components needed such as screws, nuts, bolts, clamps and standoffs.