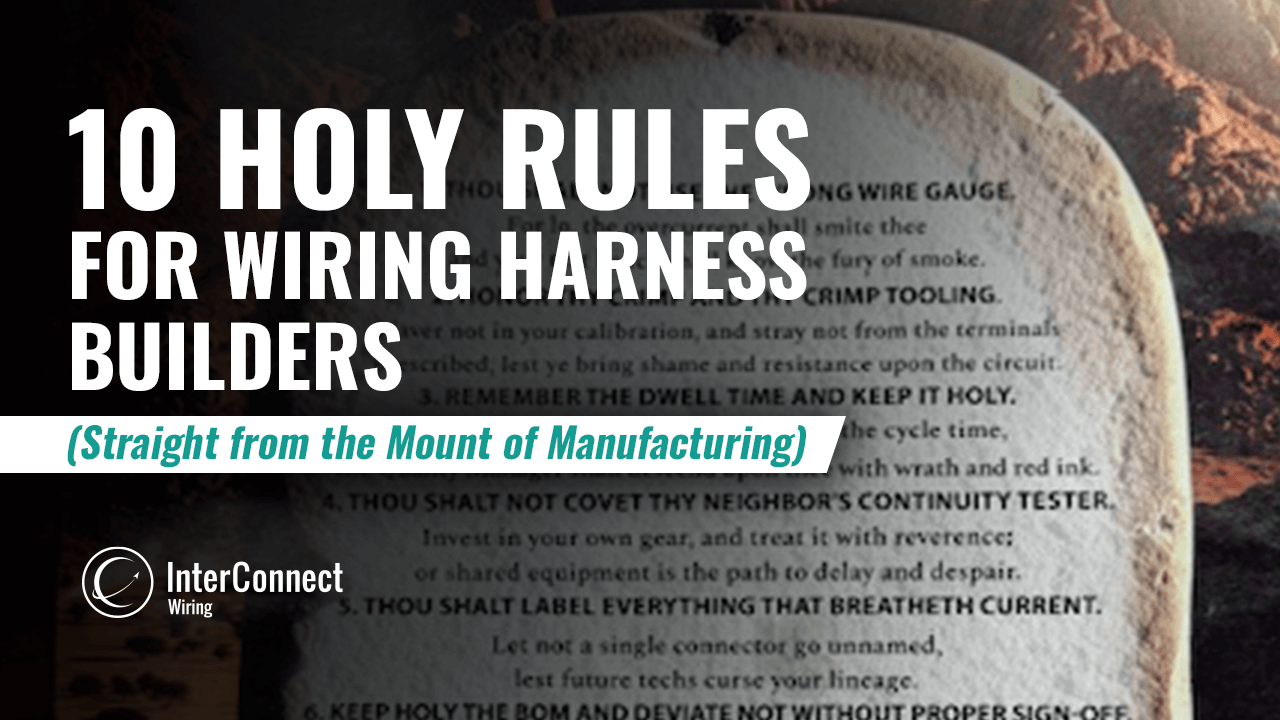

In every great trade, there are unspoken rules – the kind passed down from mentor to apprentice on the manufacturing floor. But in wiring harness manufacturing, those rules have been etched in stone. Let’s take a closer look at these “holy” rules that every harness builder, technician, and engineer will appreciate.

This list appears in Wiring Harness News, a publication dedicated to the wiring industry.

The Commandments

- Thou Shalt Not Use the Wrong Wire Gauge

There’s no quicker way to summon smoke and sparks than by choosing the wrong wire size. Precision in gauge selection isn’t just a technical detail – it’s the foundation of reliability and safety. Choose wisely, and your circuits shall live long and prosper. - Honor Thy Crimp and Thy Crimp Tooling

Your tools are sacred. Keep them clean, calibrated, and handled with care. A poor crimp can undo an entire day’s work – or worse, compromise an aircraft’s performance. At InterConnect, we treat every crimp like a signature: proof of craftsmanship and consistency. - Remember the Dwell Time and Keep It Holy

Whether soldering or testing, patience pays off. Rushing through dwell times or skipping verifications can lead to rework, delays, or failures in the field. True precision requires time, attention, and discipline. - Thou Shalt Not Covet They Neighbor’s Continuity Tester

A well-loved continuity tester is every technician’s trusted sidekick. But in the spirit of teamwork, it’s best to get your own and know it inside and out. Familiarity breeds accuracy. - Thou Shalt Label Everything That Breatheth Current

Labels are the language of clarity. A single unlabeled connector can confuse even the most experienced engineer. Proper labeling ensures traceability, reduces errors, and keeps the workflow divine. - Keep Holy the BOM and Deviate Not Without Proper Sign-Off

Tempted to substitute a part? Not without documentation. A Bill of Materials is a sacred document, built through engineering precision and testing. Respect the process (and the paper trail). - Thou Shalt Not Commit Adhocracy

Adhocracy, or the act of “making it up as you go”, is the sworn enemy of quality. Stick to the drawing, follow the spec, and trust the process. Creativity belongs in problem-solving, not in cutting corners. - Thou Shalt Route with Purpose and Tie with Grace

A well-organized harness is a work of art. Routing, bundling, and securing each wire neatly ensures not only beauty but also performance. Function and form go hand in hand. Or in this case, wire in tie. - Bear Not False Witness in the Test Report

Testing is where truth is revealed. Record accurately, report honestly, and always verify your results. The reputation of both technician and company depends on it. - Thou Shalt Not Make It Fit with a Mallet

If you need a hammer to make a connector fit, something has gone terribly wrong. Respect the design, the dimensions, and the documentation. The right fit doesn’t require force – just precision.

A Timeless Message for Modern Manufacturing

While these commandments were written with humor, they capture something every wiring harness manufacturer understands: quality is sacred. Every crimp, every tie, every label represents the dedication of the people behind the product. In an industry where precision can mean the difference between success and failure, following these guiding principles keeps us all grounded – and our circuits running smoothly.

At InterConnect Wiring, we live by these values every day. Our technicians, engineers, and quality teams work hand in hand to deliver wiring harnesses that meet the highest standards of excellence.

And so it is written: quality shall be respected, precision shall be maintained, and the humble wiring harness shall continue to power the world above us and beyond.

Photo Credit: Wiring Harness News

(For it is the inspired word of the Harness faithful.)