Anytime you enter a new industry there is a learning curve involved. I started my position one year ago off of the recommendation of a friend. I had little idea what they meant when I was told, “We make wiring harnesses”, or that there would be so many variations of our products, or how differently the aerospace industry works from what I have experienced before. Honestly I just thought that the company looked really well run, but working on amazing platforms like F-16, F-15, and UH-60 Blackhawk didn’t hurt either. My first year has been overwhelming at times but I’ve met some great people and feel like I’m finding my way.

InterConnect has one of the finest training programs for employees I’ve come across but naturally when you’re trying to take in too much information at once it doesn’t all stick. After all, InterConnect has built over 25,000 unique part numbers for aircraft electrical panels and wiring harnesses! When your customers are the giants in the aerospace & defense industry you can be sure that you’re working with the finest engineers and procurement professionals in the world. They’ve done their homework and can ask some very technical questions for a newbie.

Can you build x# of circuit breaker panels with AC & DC carrying x# of circuit breakers to J-standard specs with AS50881 laser wire marking within xx amount of days?? Additionally, can you test that for continuity, resistance, leakage, capacitance and voltage?

I got tired of saying, “I’m not sure, but I’ll find out!” To help my customers learn a few things I’ve learned to ask better questions. At face value, when asked a question like the one above, it may seem like you either can or can’t meet those requirements; however, you really can’t look at it as a simple yes or no answer. On the contrary, we should be asking pointed questions to really understand the project’s requirements. After delving in a little deeper, I find that we can either meet their needs, come up with a unique solution, or cut bait before too much time is wasted for either party. Everyone’s time is too valuable in this industry!

In summary, we come up with solutions to meet our customers’ real needs. I have learned a lot from my customers by asking a lot of good questions instead of looking at things black and white. We help solve the problem.

I’ve also learned to redefine my thinking of patience. I’ve had customers at some of the big companies like Honeywell, Northrop Grumman, and Boeing use some funny sayings about getting things done in regards to time; ‘it’s like turning the Titanic on the Mississippi’ is one of my favorites. Obviously this is to no fault of any one person or organization; it comes with the territory of building multimillion dollar aircraft. It’s just something to be cognizant of if you’re new.

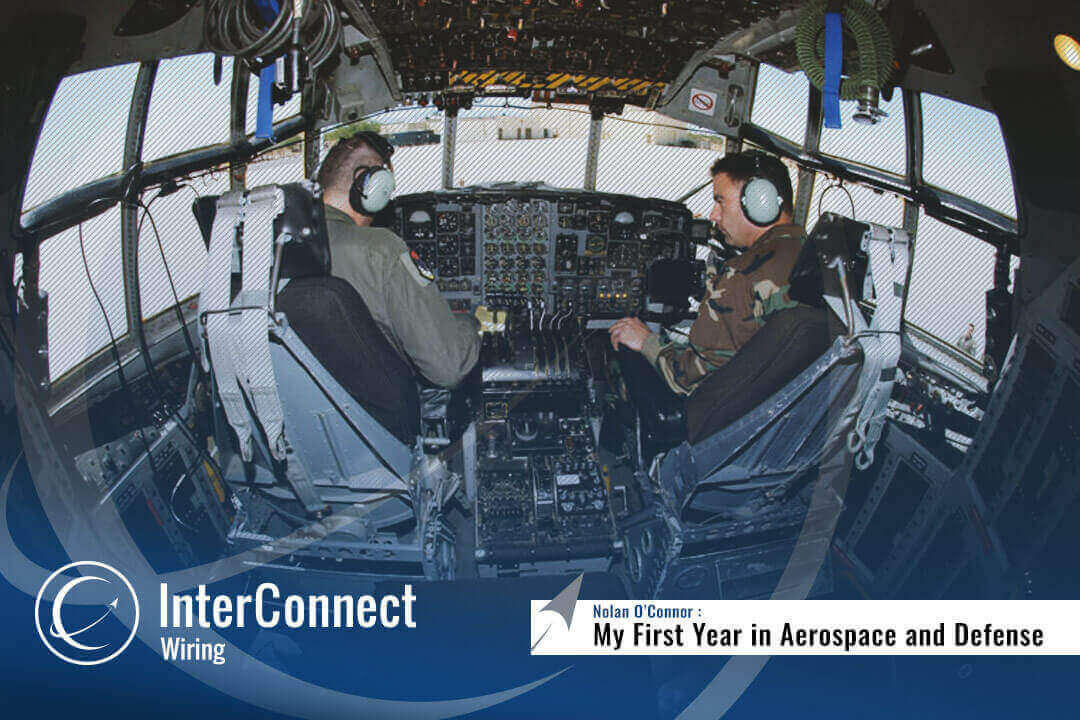

For example we have a technical services agreement or license with several of our customers like Lockheed Martin and Sikorsky in which they will provide InterConnect Wiring data on how to produce parts like cockpit panels, circuit breaker panels, wiring harnesses, or cable assemblies for their aircraft. Something like this might be used to do a complete aircraft rewire to remove old brittle, worn wiring. It took my boss nearly a year to even form the agreement on one of these before I started and here I am another year later and have just received our first complete data package. From there we still have a long process with the end user to build the harnesses and panels, ship them, fly a team into country, depopulate their aircraft, rewire, and test it. This easily can turn into a four year project but it is a real need for the end user and they appreciate the effort.

Detailed planning, asking the right questions and setting up proper expectations are keys to success in long term projects like a complete aircraft rewire. Part of being a good supplier is sticking with your customers through the long drawn out projects and processes. Ask the questions to know the project is right for both parties and then have the patience to see it through to the end. Don’t get me wrong you’ll still have plenty of customers that need those little orders yesterday just like in any other industry!

InterConnect does a little bit of work with all of the big aerospace and defense companies and most of the medium ones too. One thing that I’ve noticed is that many of the OEMs are working toward a smaller, more centralized supply base. Information is now ubiquitous. Now is the time to start asking the right questions and really embrace transparent selling and present your customer with the solution that fits their needs best. Ask the right questions so that you may set the right expectations to build strong long lasting relationships.

I still don’t know all there is to know about relay panels or the multitude of testing methods we utilize for military aircraft like B-1B, B-52, E-4B or F-35 but I have learned that our customers are some of the best learning resources out there! Please subscribe to our blog and share with us what you’ve learned about our industry or other tips for those of us still a little green! And for those who are new like me, you can see some pictures of electrical aircraft products here.

InterConnect Wiring is the global leader in rewiring aircraft as well as manufacturing key electrical products including wiring harnesses, cockpit panels, power distribution panels, and relay assemblies. Customers include the US Army, Air Force and Coast Guard, as well as Lockheed, L-3, Sikorsky, BAE, Boeing, and Bell. Platforms we support include the F-16, C-130, F-15, F-2, F-35, UH-60, H-92, MH-60, and V-22.

For aerospace defense and commercial companies who seek a premium wiring and electrical manufacturer and installer, InterConnect implements the processes and services that lead to a successful project delivered on time. We are also there to rescue endangered projects when others fail. The only thing better than saving a project in danger is doing it right in the first place = InterConnect Wiring.

Nolan O’Connor is a Regional Sales Executive for InterConnect Wiring.